Choosing the right inground pool for your home is a big decision that impacts your enjoyment and wallet for years to come. When comparing precast concrete and fiberglass pools, most homeowners focus on cost, customization options, and long-term maintenance requirements.

Both precast concrete and fiberglass pools typically cost between $45,000 and $90,000 initially, but fiberglass pools generally have lower long-term maintenance costs.

We’ve found that concrete pools offer more flexibility in size and shape, making them popular with homeowners who prioritize customization.

Fiberglass pools, on the other hand, come as pre-manufactured shells that are installed more quickly but with limited design options. This makes concrete pools better for unique spaces or specific design visions, while fiberglass shines when installation speed matters.

Beyond the upfront costs, we need to consider the total ownership experience. Fiberglass pools typically require less maintenance and fewer chemicals, which saves both time and money.

Concrete pools may need more frequent cleaning and eventual resurfacing. Your choice ultimately depends on whether you value customization options or easier maintenance as your top priority.

In this article, you’ll learn how precast concrete and fiberglass pools compare in cost, installation, durability, and long-term performance.

Here’s what you need to know:

- Precast concrete pools explained

- Fiberglass pools uncovered

- Cost, time, and installation differences

- Comparing long-term durability and performance

- Plunge pool suitability: Which is better?

Let’s break down the key differences to help you choose the right material for your plunge pool project.

Precast concrete pools explained

Precast concrete pools offer homeowners a durable, customizable swimming solution that combines strength with design flexibility. These pools are manufactured off-site and delivered ready for installation, making them different from traditional poured-in-place concrete pools.

How precast concrete pools are made and installed

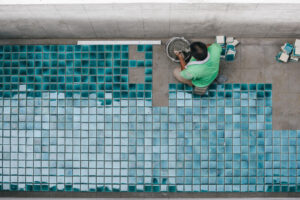

Precast concrete pools are manufactured in controlled factory environments using specialized forms. Concrete is poured into these molds and reinforced with rebar or steel mesh for added strength. This process ensures consistent quality and fewer imperfections than on-site concrete work.

Installation begins with excavation and site preparation. The precast shell arrives by truck and is carefully lowered into the prepared hole using a crane. This method significantly reduces on-site construction time compared to poured concrete pools.

The sections are sealed together if the pool arrives in multiple pieces. Then plumbing and electrical components are connected, and the surrounding area is backfilled. The entire installation process typically takes 2-3 weeks, depending on weather and site conditions.

Durability, style, and structural qualities

Precast concrete pools offer exceptional structural integrity. They can withstand ground movement better than many alternatives and don’t flex or warp over time. These pools typically last 30+ years with proper maintenance.

The concrete structure allows for various finishes including plaster, tile, aggregate, and specialized coatings. This versatility gives homeowners extensive design options to match their landscape and aesthetic preferences.

Weight is both an advantage and consideration. The heavy structure resists “floating” in areas with high water tables, but requires proper engineering and sometimes additional structural support. The concrete shell maintains water temperature consistency but may take longer to heat initially.

Popular uses: Plunge and dipping pools

Precast concrete excels in smaller formats like plunge and dipping pools. These compact pools (typically 10-15 feet long) provide refreshing relaxation without requiring extensive yard space.

Plunge pools often feature built-in seating and can incorporate water features like jets or waterfalls. Their smaller water volume makes maintenance more manageable and reduces chemical and heating costs compared to full-sized pools.

Many homeowners choose precast concrete plunge pools for therapy purposes. The solid structure accommodates powerful jets for hydrotherapy, and the concrete walls can be insulated for year-round use in various climates.

Exercise enthusiasts appreciate that some models can be equipped with swim jets, creating resistance for stationary swimming in a compact footprint.

Fiberglass pools uncovered

Fiberglass pools offer a unique set of characteristics that set them apart from other pool types. They provide a smooth, non-porous surface and typically require less maintenance than concrete alternatives.

Manufacturing process and transportation

Fiberglass pools are manufactured in a factory setting under controlled conditions. The process begins with a mold that creates the pool’s shape and features. Multiple layers of fiberglass, resin, and other materials are applied to form a strong, one-piece shell.

The finished shell includes a special gel coat that gives the pool its color and smooth finish. This coating is designed to resist UV damage and provide a barrier against water absorption.

Once completed, the entire pool shell is loaded onto a truck for delivery. Transportation can sometimes be challenging due to the shell’s size. Width restrictions may limit the pool dimensions to what can legally travel on highways.

Most manufacturers offer various pre-designed shapes and sizes to accommodate different yard layouts and preferences. The factory-controlled environment helps ensure consistent quality and structural integrity across all pools.

Ease of installation and shape limitations

Fiberglass pools can be installed much faster than concrete pools. A typical installation takes about 2-3 weeks compared to 2-3 months for concrete.

The installation process involves:

- Excavating the hole

- Creating a sand or gravel base

- Lowering the pre-made shell into position

- Filling with water while backfilling around the sides

- Completing the surrounding deck and equipment setup

One significant limitation is that fiberglass pools come in predetermined shapes and sizes. Unlike concrete, they cannot be fully customized to unusual dimensions or completely unique designs.

The maximum size typically ranges from 16-18 feet wide and 35-40 feet long due to shipping restrictions. Larger sizes are available but may require special permits for transportation.

Maintenance needs and common repairs

Fiberglass pools generally require less maintenance than concrete pools. The smooth, non-porous surface resists algae growth and requires fewer chemicals to maintain proper water balance.

According to the Center for the Polyurethanes Industry (via CFFA), fiberglass pools offer lower maintenance costs due to their non-porous surfaces, which resist algae and reduce the need for frequent chemical adjustments.

Routine maintenance includes:

- Regular water testing and chemical balancing

- Standard filtration and cleaning

- Occasional surface cleaning to remove buildup

The gel coat surface can sometimes develop issues such as fading, crazing (small cracks in the gel coat), or blistering. These problems are typically cosmetic rather than structural.

Spider cracks may appear in the gel coat but rarely affect the pool’s structural integrity. More serious issues like bulging walls can occur if water accumulates behind the shell due to improper installation or drainage problems.

Most fiberglass pools come with lengthy warranties, often 25+ years on the structure. However, the gel coat surface typically has a shorter warranty period of 5-15 years depending on the manufacturer.

Cost, time, and installation differences

When choosing between precast concrete and fiberglass pools, three factors significantly impact your decision: upfront costs, installation timelines, and the complexity of the setup process. Both options have distinct advantages and limitations in these areas.

Precast concrete pool setup process

Precast concrete pools require substantial site preparation before installation begins. The process starts with excavation, followed by creating a base layer of sand or gravel. Then, precast concrete panels are delivered and carefully positioned using heavy machinery.

The panels must be sealed together properly to ensure watertightness. This typically involves applying special sealants at the joints. After panel installation, plumbing and electrical systems are connected.

The final steps include backfilling around the structure, installing coping and decking, and applying interior finishes. This multi-stage process typically requires specialized contractors and can take 6-10 weeks to complete, depending on weather conditions and project complexity.

Fiberglass pool installation timeline

Fiberglass pools offer a significantly faster installation timeline than their concrete counterparts. The entire process typically takes just 3-5 weeks from start to finish.

The installation begins with excavation, followed by creating a sand or gravel base. The one-piece fiberglass shell arrives pre-manufactured and is lowered into the prepared hole using a crane.

Once positioned, installers connect the plumbing and electrical components. The area around the shell is then backfilled, and final elements like coping, decking, and equipment are installed.

The rapid installation is possible because the shell comes ready-made. This means you can be swimming much sooner, which is especially valuable if you’re installing during the swimming season.

Budget ranges and hidden fees

A standard fiberglass pool typically costs between $45,000 and $75,000 for complete installation. Precast concrete pools generally run from $50,000 to $90,000 for similar sizes.

| Feature | Fiberglass Pools | Precast Concrete Pools |

| Initial Installation | $45,000-$75,000 | $50,000-$90,000 |

| Annual Maintenance | ~$400 | $1,000+ |

| Installation Time | 3-5 weeks | 6-10 weeks |

Be aware of potential hidden costs with both options. For fiberglass, delivery charges can increase significantly if you’re far from the manufacturer. Access issues might require special equipment, adding to costs.

With precast concrete, site preparation costs can escalate if soil conditions are poor. Interior finish options like plaster or tile add to the base price. Long-term maintenance is also higher for concrete pools, requiring more chemicals and potential resurfacing every 7-10 years.

Comparing long-term durability and performance

The durability and performance of your pool over time will significantly impact both enjoyment and overall value. When comparing precast concrete and fiberglass, several key factors determine how well each material stands up to the elements and regular use.

How each handles climate, wear, and UV exposure

Precast concrete pools offer excellent structural strength but can be vulnerable to certain conditions. In regions with freeze-thaw cycles, concrete may develop cracks over time as water seeps into tiny pores and expands when frozen.

Fiberglass pools handle temperature fluctuations better due to their flexible nature. Their gel coat surface provides good UV protection, preventing fading and deterioration from sun exposure. However, this coating can eventually fade or blister after prolonged sun exposure.

Both materials handle regular wear differently. Concrete surfaces can become rough over time, potentially causing discomfort for swimmers. Fiberglass maintains its smooth surface but may show spider cracks if the ground shifts significantly.

In coastal areas, saltwater affects concrete more severely than fiberglass, potentially leading to faster deterioration.

Lifespan and repair difficulty

When properly maintained, concrete pools typically last 30+ years, while quality fiberglass pools can last 25-30 years. The difference in longevity often comes down to maintenance practices rather than the material itself.

Concrete pools require more frequent maintenance, including:

- Resurfacing every 10-15 years

- Regular acid washing

- More intensive cleaning routines

Fiberglass repairs can be challenging since they must match the existing gel coat exactly. When damage occurs, it often requires professional intervention. The good news is that such repairs are needed less frequently.

Concrete offers an advantage in repairability – patches and resurfacing can be done without difficulty by professionals. This makes concrete pools easier to restore when damaged, though they need this attention more often.

The National Plasterers Council notes that concrete pools generally require resurfacing every 10 to 15 years, depending on water quality and care.

Plunge pool suitability: Which is better?

Plunge pools have become increasingly popular for urban homes and small spaces. The choice between precast concrete and fiberglass affects both how your pool looks and how it fits in your yard.

Design flexibility and aesthetic possibilities

Precast concrete plunge pools offer significant customization options. We can shape, size, and finish concrete pools in countless ways to match your vision. Color options include various aggregate finishes, tiles, and interior coatings.

Fiberglass plunge pools come in pre-designed shapes and sizes. While this limits customization, manufacturers now offer stylish modern designs. The smooth gel coat surface of fiberglass pools provides a sleek look and comfortable feel against the skin.

Concrete pools allow for integrated features like tanning ledges or built-in seating. Fiberglass models have these features pre-molded, which can look elegant but can’t be changed after manufacturing.

For unique aesthetics, concrete holds the advantage. For quick installation with contemporary appeal, fiberglass makes a strong case.

Compact site requirements

Plunge pools excel in small spaces, but installation requirements differ between materials. Concrete plunge pools typically need more installation space around the actual pool for forming and pouring.

Fiberglass plunge pools arrive as complete shells, requiring less workspace during installation. This makes them ideal for urban properties with tight access. Many fiberglass models can be craned into place in a single day.

Concrete pools generally need more extensive excavation and site preparation. The building process creates more disruption and takes longer.

For properties with limited access or tight spaces, fiberglass holds a clear advantage. The simplified installation process minimizes site impact and speeds up completion time.

Conclusion

Choosing between precast concrete and fiberglass pools comes down to your specific needs and priorities. Both options offer quality swimming experiences but with different advantages.

Fiberglass pools provide faster installation and lower maintenance costs over time. Their smooth surface resists algae growth and doesn’t need resurfacing, making them user-friendly for busy homeowners.

Precast concrete pools shine in customization possibilities. They can be built to any size or shape you desire, perfect for homeowners with specific design visions.

Budget considerations should include both initial installation and long-term maintenance. While fiberglass may have similar upfront costs to concrete, the lifetime maintenance expenses tend to be lower.

Durability factors differently between these options. Concrete pools typically last longer overall but require more care, while fiberglass offers excellent durability with minimal upkeep.

We recommend consulting with multiple pool contractors before making your final decision. Getting several quotes and design proposals will help you visualize your options and understand the true costs involved.

Your climate, soil conditions, and planned usage should also influence your choice. The perfect pool for your neighbor might not be the perfect pool for you.

Get a custom quote today to compare precast concrete and fiberglass pool options based on your backyard, budget, and design preferences.